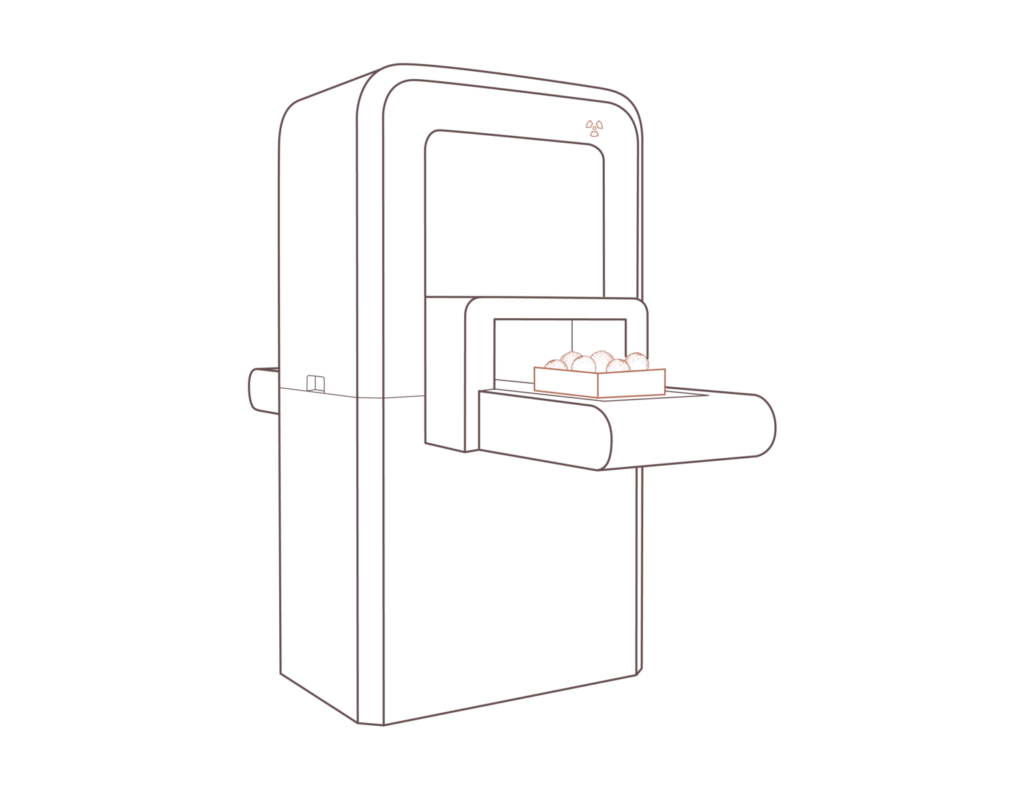

Q Eye XP - In-line X-ray System for Internal Quality and Safety

Q Eye XP, the only end-of-line X-ray Food Inspection System, guarantees Safe and High-Quality Fruit and Vegetable Products. Request your free Consultation now.

Q Eye XP, The only X-ray INSPECTION System for final Safety and Internal Quality checks

Ensure Safe and High-Quality Fruit and Vegetable

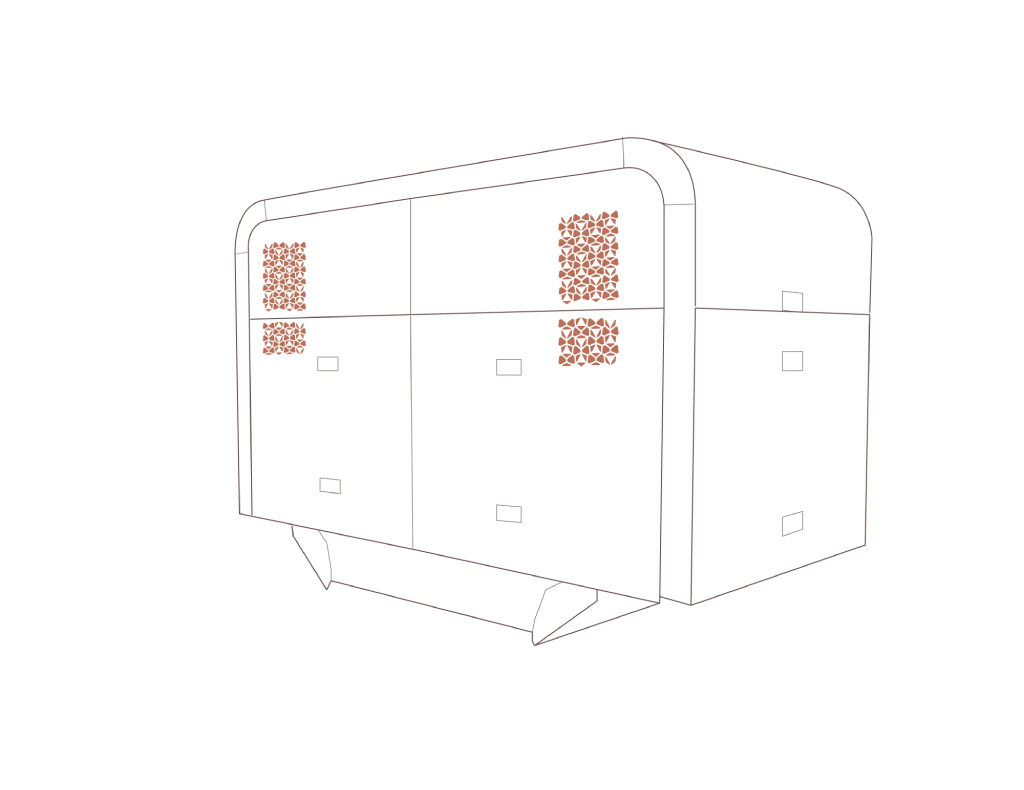

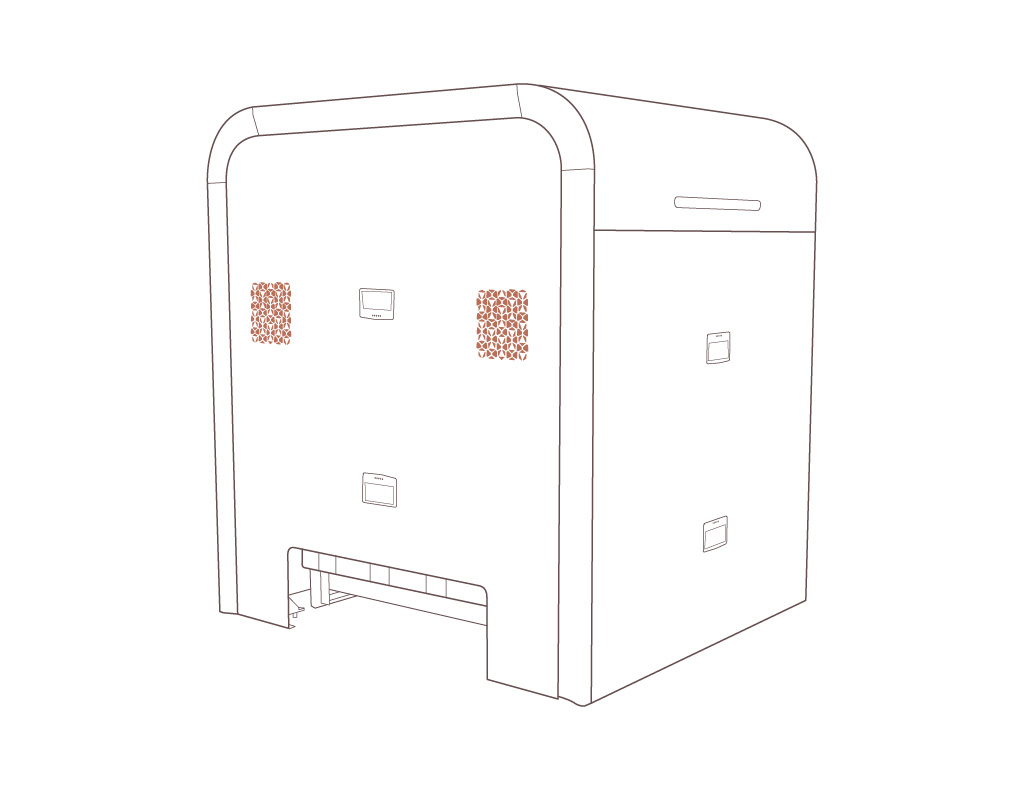

BIOMETiC’s Q Eye XP is the unique X-ray inspection system for fruit and vegetable in boxes. It performs final safety and internal quality checks and detects defects that often occur between storage and delivery processes, such as oxidation or internal defects due to pests and insects.

Q Eye XP can be integrated into the packaging line of a packhouse or positioned in the goods receiving area of a supermarket as a stand-alone system.

Q Eye XP, The X-ray Inspection System of Fruit and Vegetable Boxes

The Difference between a Conventional X-ray Device and Q Eye XP

Q Eye XP is the first and only X-ray system on the market for final inspection of fresh produce’s safety and internal quality inside boxes.

Compared to a conventional X-ray inspection solution, Q Eye XP is the only X-ray scanner that performs the ultimate accurate safety and internal quality check of fresh produce in boxes before they reach customers and end consumers.

Like all BIOMETiC solutions, Q Eye XP is adaptable to different types and varieties of products and can be customized according to our customer’s inspection needs: From simple detection of rot to internal defects caused by insects. Its X-ray scanning technology is complemented by dedicated algorithms using artificial intelligence, which allows it to capture and recreate in detail the internal quality characteristics of fruits and vegetables.

Q Eye XP performs Fruit and Vegetable X-ray Inspection and Control for Internal Quality in the smallest Details

Examples of Applications of Q Eye XP X-ray Inspection

Thanks to its compact size, Q Eye XP can perform accurate food safety and internal quality checks either as an integrated solution in a fruit and vegetable cooperative’s packaging line or as a stand-alone solution in a supermarket’s goods receiving area.

The mathematical algorithms used are, in fact, adaptable to the product to be scanned and to the defects to be detected. Q Eye XP checks and detects any foreign bodies or internal quality defects in fruit and vegetables in boxes.

Q EYE XP IN YOUR PRODUCTION LINE OR RETAIL STORE

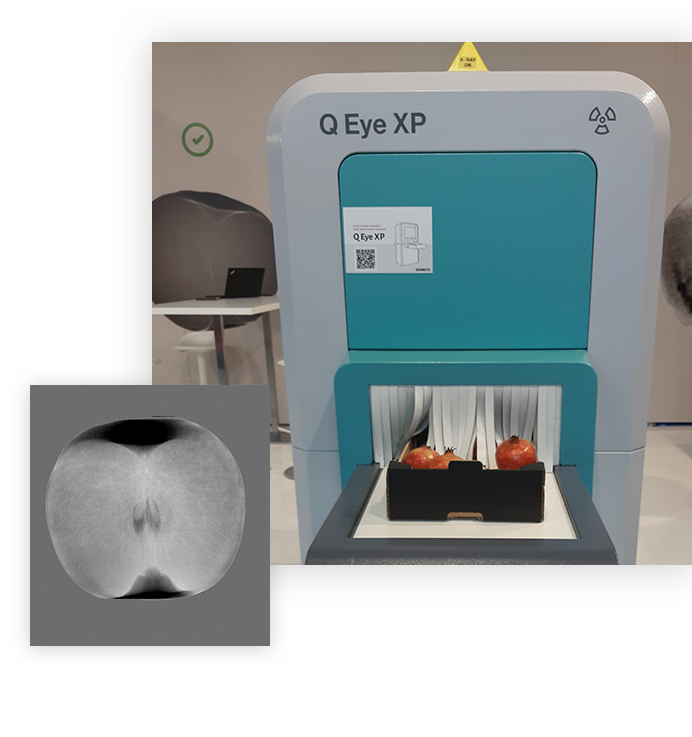

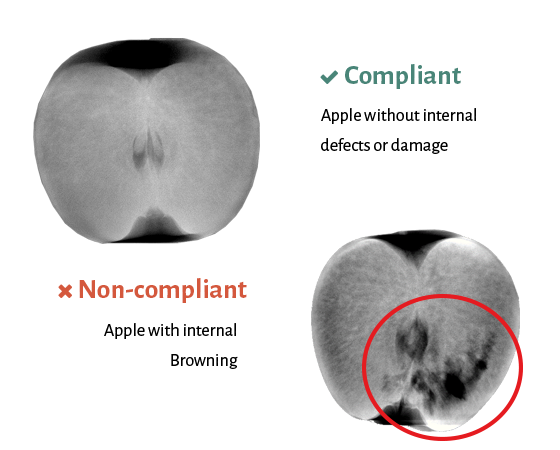

Examples of Q EYE XP X-ray Inspection results for boxed Fruit and Vegetable

Possible Scan Results

Each products, like each sector of the fruit and vegetable industry, has its own specific characteristics. That’s why the real added value of Q Eye XP is the fact that it is versatile and customizable.

Here are just some examples of problems that Q Eye XP can detect in different types of fruits and vegetables:

- Detection of cavities in the pulp and gaps between pulp and skin in boxed fruit, often indicators of very ripe fruit, rot, or inferior pulp quality (e.g., avocados, mangoes, apples, citrus, nuts)

- Detection of fruits with sprouted or dead seeds (e.g., mangoes, avocados)

- Identification of fruits and vegetables with quality defects due to environmental problems (e.g., potatoes with hollow heart, avocados with hail damage)

- Identification of fruits with a black heart (e.g., pomegranates, potatoes, apples)

- Detection of damage caused by Asian bug insects (e.g., apples) or moths of type false codling moth (FCM) (e.g., citrus)

- Detection of fruits with differences in texture, coloration, and moisture percentage in the pulp (e.g., apples, dates, mangoes, etc.)

- Determination of weight of individual products in fruit and vegetable boxes and packages (e.g., dates, apples, citrus, avocados, etc.)

- ...

Q EYE XP, The only X-ray Inspection System for Final Safety and Internal Quality Checks

Why our Customers choose our X-Ray Inspection System Q Eye XP

We know that each sector and each company is unique and has different needs. For this reason, the real added value of BIOMETiC lies in the adaptation of solutions to the specific needs of cooperatives and large-scale retail trade with multiple possibilities of safety and internal quality inspections of fresh produce.

Born out of BIOMETiC’s more than 40 years of experience in manufacturing in-line inspection systems, Q Eye XP is an X-ray inspection system designed explicitly for cooperatives, retailers, and their needs: from protecting brand reputation to eliminating waste for optimized production.

That’s why our customers have come to rely on Q Eye XP:

Increases product safety and quality

Compared to a conventional X-ray inspection solution, the big advantage of Q Eye XP is that it provides a tighter, less wasteful final food safety and internal quality check by adapting mathematical algorithms based on the product being scanned. Q Eye XP is the only X-ray inspection system on the market for final inspection of fresh fruit and vegetables in boxes, identifying defective, damaged, or contaminated packages and products.

Adaptable to products and producer needs

Q Eye XP grows with your company’s needs. It adapts to each type of product to be analyzed and to your needs as a manufacturer. That’s why Q Eye XP is suitable for final inspection both in packaging lines and in the goods receiving area of a supermarket, where it is even more important to ensure safe, first-class products for consumers.

Delivers substantial savings

With Q Eye XP, you can scan and sort fresh fruit and vegetables in boxes according to internal quality, contaminants, shape, and weight to deliver safe, high-quality products to your consumers. With Q Eye XP, you no longer have to discard entire batches, only individual defective, damaged, or contaminated products. It goes without saying that this translates into significant savings.

Protects brand reputation and optimizes production

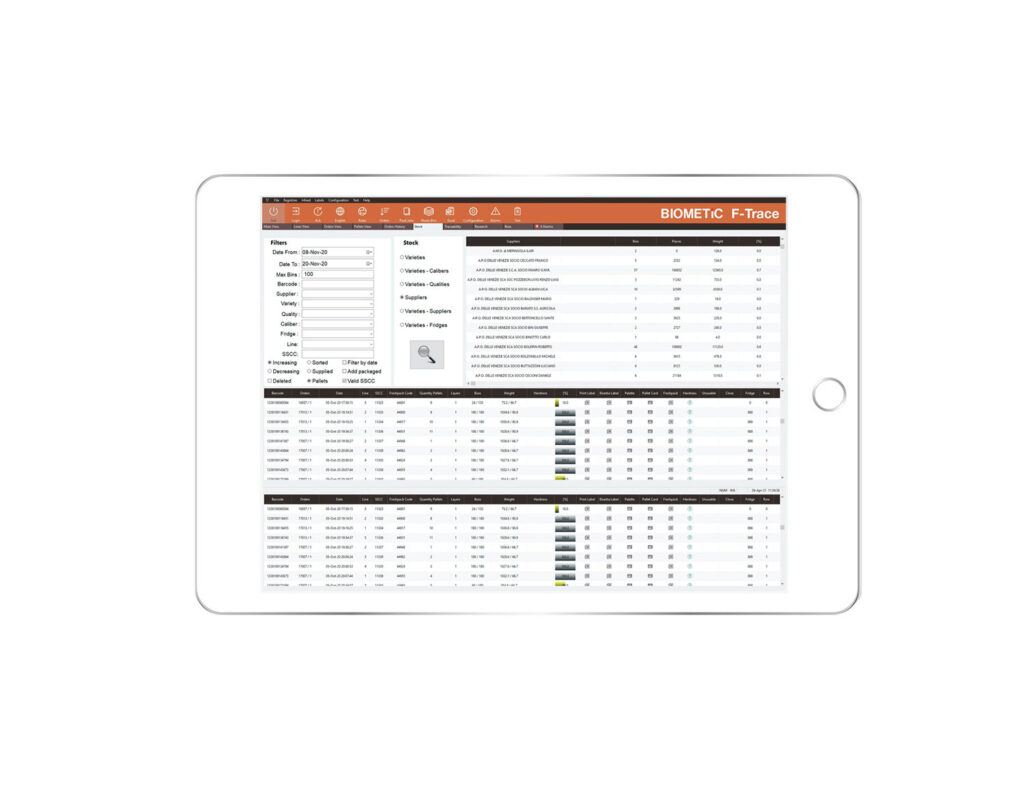

Q Eye XP can achieve these results as a single system integrated into packaging lines or as a stand-alone system in the goods receiving area of supermarkets. But it can also be integrated into the production line with the complete F-Trace solution, which automatically monitors and optimizes processes to ensure full traceability of fruit and vegetable products. Cooperatives can thus improve the entire production flow and maximize the production efficiency of the whole line.

Simple and intuitive to use

Q Eye XP is easily integrated into any production line and has a user-friendly interface that makes its operation quick and intuitive for the operator. Training is given when the machine is installed. Should training for other operators be required at a later date, an extra Q Eye XP training package can be added at any time.

It can be used in any industrial or supermarket packaging line

Q Eye XP can be easily integrated and commissioned into an existing industrial packaging line or installed as a stand-alone solution in a supermarket. It features an internal sealed X-ray shielding that ensures total operator safety when using the system.

Verifies products with high-resolution images in total safety

Q Eye XP uses artificial intelligence, proprietary electronic sensors, and X-rays to get better images and apply a non-destructive technology that safeguards the internal quality of fruit and vegetable products. Its ultra-high image processing speed and a product scanning speed of up to 36m/min on the belt ensure effective detection of contaminants and internal quality defects.

In-line food inspection and control with innovative technologies

BIOMETiC Products integrable into your Production Line

Do Not Hesitate to Contact Us

We are at your complete disposal. We would be happy to provide you with our know-how and free consulting services to select the best BIOMETiC solution for your food inspection and fruit sorting needs.

Contact us now, and let’s discuss how we can make your food products and fresh produce better and more secure than ever before.