Delivering Safe and Top-Quality Bakery Products

According to BAKERpedia, in an ideal world, when it comes down to determining how well the final baked products meet customer quality expectations, bakery manufacturers would make each product with exactly the same quality characteristics to deliver delicious and nutritious baked goods to their customers consistently. And this would satisfy customers 100% of the time.

However, in the real world, bakers know that their products will have some variations in the production process. And naturally, the question of how to guarantee consistent food safety and quality arises here.

Challenges in Food Safety and Quality Controls for Bakery Manufacturers

As with all things in food manufacturing, you can only control what you detect and measure. This is why large industrial bakeries began to rely on detection methods and inspection systems to prevent quality defects in food processing and assess the quality characteristics of their baked products.

As the qualitative, textural, and sensory properties of yeast- and chemically-leavened products are defined by the crumb structure, one of the solutions bakery manufacturers often count on are, e.g., labor analyzers that perform crumb analysis of sliced surface areas of baked product samples. However, it might go without saying that sample analyses, which are not performed in-line, are often not reliable enough to guarantee baked products with consistent quality characteristics and free of foreign materials.

Luckily, as also Sherry Williamson, MBA – Vice President of Global Quality and Food Safety at the Kellogg Company – states in her article “Is Zero Foreign Material Possible in Food Processing?” guaranteeing complete food safety to the consumers and protecting the brand reputation is possible with the help of in-line detection systems. If leveraged correctly, such detection systems can significantly impact an organization’s journey to zero foreign material.

And this is when BIOMETiC Mito, the only 3D X-ray inspection system for the food industries, comes into play.

How BIOMETiC Mito Helps You Guarantee Safe and High-Quality Bakery and Baked Products

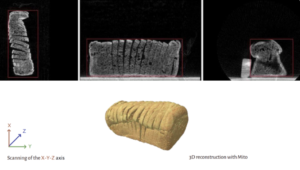

At BIOMETiC, we have always invested in research and development to find the best solutions that meet the needs of the food industry. And this is why we have developed Mito, the only computed tomographer for food industries with unique real-time 3D X-ray inspection.

Mito guarantees a complete product inspection and is already successfully implemented, e.g., at LATTERIA VIPITENO and MENZ&GASSER.

Compared to conventional multi-source and multi-sensor X-ray technology inspection systems with 2D technology, Mito combines X-rays technology with 3D computed tomography (CT) and artificial intelligence (AI). Mito’s real-time 3D X-ray scanning technology thus translates into more precise and strict in-line food safety and quality controls with fewer errors and waste.

How We Ensure You Safe and High-Quality Baked Products

Thanks to its real-time 360° X-ray scanning technology, Mito allows you to guarantee your customers not only foreign body-free baked goods but also high-quality food products:

- Identification and expulsion of products with internal quality defects

- Controlling the balanced distribution of ingredients to ensure a uniform product

- Control of the dosage of the products to avoid waste and guarantee a first-quality product

- Analysis of product surfaces to expel foods with damaged or missing areas

- Recognition of foreign bodies, such as glass and metal fragments as well as dough clumps