- Company

-

-

-

-

NEWS & EXPERTISE

- Case Studies & References

- Trade Fairs & Events

- Blog

- FAQ

-

-

-

- Products

-

-

-

-

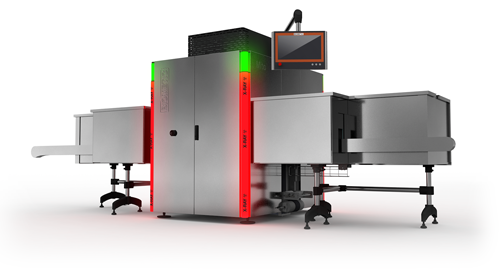

Mito - Unique 3D X-ray Food Inspection System

-

Q Eye Smart - AI Optical Sorter for Fruit and Vegetables

-

Q Eye Spectro - Internal Quality Scanner for Fruit and Vegetables

-

Q Eye X - In-line X-ray Grading System

-

Q Eye Stereo - AI Planning Solution for Fruit Cooperatives' Efficiency

-

Tally - Control and Optimization of Fruit and Vegetable Sorting

-

Q Eye XP - In-line X-ray System for Internal Quality and Safety

-

F Trace - Software for Complete Food Traceability

-

-

-

- Applications

-

-

-

-

FOOD INDUSTRY APPLICATIONS

-

FRUIT AND VEGETABLES INDUSTRY APPLICATIONS

-

-

-

-

- 24/7 Support

- Your Solution

- Contact Us